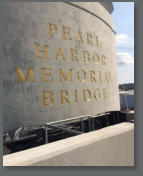

Case Study: Q-Bridge

A few years back we did a set of True Prismatic mold letters for a

bridge in Connecticut. But in this case the letters were being attached

to the inside of a curved steel form (you can see the curve of the piling

in photos 1 and 2). The HDU was too brittle to be used here. It would

have broken when they tried to force it to the curve of the form. Plus,

the mold letters had to hold up for two pours.

So what we had to do was to hand-carve the reversed letters out of 2"-

thick HDU and then fill and prime the HDU to give it a smooth, non-

porous surface (In the first photo below we are sanding the carved and

primed letter). We then made silicone molds of these HDU letters

(Photo showinf the orange silicone mold within a blue foam retainer).

Then we cast a tough but slightly flexible copy of the HDU letter we

had carved (Photo of amber-colored reversed "P"). This gave the

customer a mold letter that was True Prismatic, flexible enough to

conform to the curve of the steel form and tough enough to withstand

multiple pours.

True Prismatic

Now the V-Bottomed molds we've been talking about are the

Simulated Prismatic style. This is a very affordable way to go. But

sometimes only the Real Deal will do - True Prismatic Letters! To do

this we actually hand-carve the letters in HDU foam. These are truly

works of art. But, because they are made of HDU foam, they are not as

durable as the Duro-Tek letters, nor do they have the smooth, non-

porous edge that Duro-Tek has. That means that the letters have to be

filled and painted, and even then a mold release agent will be

necessary.

Also, due to all the hand-labor, these mold letters are more expensive

then the V-Bottom and Flat-Bottom products. That said, though, True

Prismatic letters are really special.

So, since the Flat-Bottom letter molds are easier to make and can be

made with thinner sheets of Duro-Tek, they are often the least

expensive way to go.

Case Study: Q-

Bridge

A few years back we did a set of True

Prismatic mold letters for a bridge in

Connecticut. But in this case the

letters were being attached to the

inside of a curved steel form (you

can see the curve of the piling in

photos 1 and 2). The HDU was too

brittle to be used here. It would have broken when

they tried to force it to the curve of the form. Plus,

the mold letters had to hold up for two pours.

So what we had to do was to hand-carve the

reversed letters out of 2"-thick HDU and then fill and

prime the HDU to give it a smooth, non-porous

surface (In the first photo below we are sanding the

carved and primed letter). We then made silicone

molds of these HDU letters (Photo showinf the

orange silicone mold within a blue foam retainer).

Then we cast a tough but slightly flexible copy of the

HDU letter we had carved (Photo of amber-colored

reversed "P"). This gave the customer a mold letter

that was True Prismatic, flexible enough to conform

to the curve of the steel form and tough enough to

withstand multiple pours.

True Prismatic

Now the V-Bottomed molds we've been

talking about are the Simulated

Prismatic style. This is a very affordable

way to go. But sometimes only the Real

Deal will do - True Prismatic Letters! To

do this we actually hand-carve the letters

in HDU foam. These are truly works of

art. But, because they are made of HDU

foam, they are not as durable as the

Duro-Tek letters, nor do they have the

smooth, non-porous edge that Duro-Tek

has. That means that the letters have to

be filled and painted, and even then a mold release agent

will be necessary.

Also, due to all the hand-labor, these mold letters are

more expensive then the V-Bottom and Flat-

Bottom products. That said, though, True Prismatic

letters are really special.

So, since the Flat-Bottom letter molds are easier to make

and can be made with thinner sheets of Duro-Tek, they

are often the least expensive way to go.